THE WURTS FAMILY OF BUCKS COUNTY

BY TOM FRASCELLA JULY 2012

The story of San Felese immigration to the United States was affected by many people, events and conditions on both sides of the Atlantic. Some individuals in that story, more than others, share a place that requires their individual acknowledgement. Among those individuals who hold a special place are the Wurts brothers, John, William and Maurice. The Wurts brothers were descendants of a prosperous Philadelphia mercantile family and lived in the earliest days of our Republic. It is believed that the family name was originally Wurtz and the family had strong ties in the Bucks County region as well as the City of Philadelphia. Enterprising and ambitious the successful Wurts brothers aggressively sought new business opportunities in the early days of the American Republic. The Wurts’ brothers recognized that America’s infant manufacturing industry was severely hampered when the British cut off the supply of Bituminous coal during the war years. The British were the sole supplier of Bituminous coal to the U.S. which provided the fuel for iron production in America’s early iron foundries.

The Wurts brothers were aware of the discovery in the 1780’s of large deposits of Anthracite coal in northeast Pennsylvania. This harder form of coal had been the subject of early American experimentation attempting to develop furnaces that could efficiently burn the material. Some limited success in using the material for home heating had occurred by the 1820. The secret to using the material was to insure sufficient air flow from beneath to supply oxygen to the burning coal. The brothers reasoned that if Anthracite coal could replace Bituminous coal as an American energy source for manufacturing then the abundant resource could mean energy independence for the Country and great profits for the brothers.

Three problems stood in the way of this idea. First, convincing industry to convert and invest in a new energy technology. Second, obtain and secure the mineral in sufficient supply to meet the demand that would be created. Lastly, to devise a way to mine and transport the mineral from northeast Pennsylvania cheaply and efficiently across the Allegany Mountains to the population and manufacturing centers in Philadelphia and New York. In the 1820’s the possibility of success for such an large undertaking must have seemed remote as best. The Wurts brothers were however not deterred by the scope of the problems.

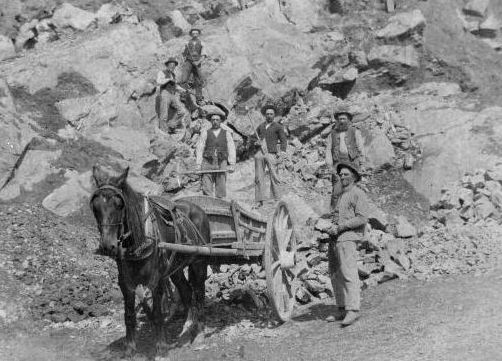

Initially they started their venture but securing inexpensive mineral rights to a number of large coal deposits. Many of the initial deposits were relatively close to the surface allowing for easy and inexpensive surface mining.. The area where they concentrated their mineral purchases and mining operation became known as the Carbondale region of Pennsylvania. At the time they began to purchase mineral rights the mineral deposits had no market and no easy transportation to markets. Therefore the mineral rights the Wurts brothers purchased were available a bargain prices. By the time the brothers had secured sufficient mineral rights to meet what they anticipated would be the future demand continued advances in burning techniques had progressed enough to make the material appear marketable and investor interest in their proposal rose. What remained was to develop a way to bring the material cheaply and efficiently from West of the Alleghany mountains to the East coast.

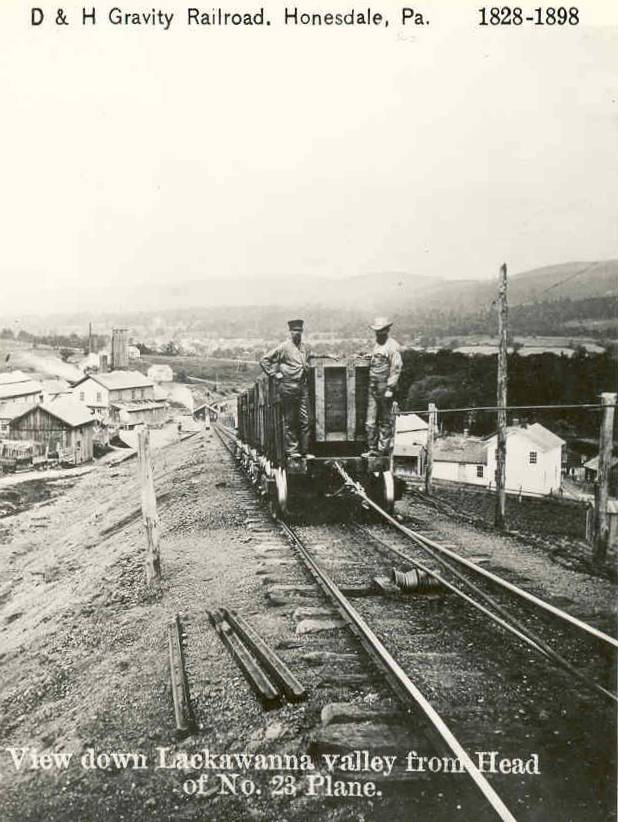

The late 1820’s was a period just before the practical availability of rail steam locomotion so that mode of delivery was not available in the brothers’ original plans. Instead the Wurts brothers devised and proposed building a “gravity” based rail system to haul the material over the mountains from the coal fields in Carbondale across the mountains to Honesdale Pennsylvania on the east side of the Alleghany mountains. Today we are so accustomed to rail cars being pulled or pushed by locomotive engines that it is hard to conceptualize of a rail line operating on a different principle. What the Wurts brothers proposed was a gravity system to be built in small sections with coal cars being moved up a mountain slope by pulleys and weights one slope and down the next at a time.

Once the rail line was built to Honesdale they proposed shifting the next phase of the journey to barges by building a canal from Honesdale to the Hudson River. Barges would then carry the material down the Hudson River for delivery to the port of New York.

Photograph of the D&R Canal barge terminal at Honesdale

What the brothers proposed to do in the time frame of the late 1820’s was a project of immense difficulty and expense. Formidable obstacles natural, economic and engineering would have to be overcome. They literally were proposing to create an industry and transportation system where none existed in the middle of what was then still the western wilderness of the United States. In addition almost all of the construction work would have to be accomplished using either animal or manpower alone.

Mules towing barges along the Canal

However the potential profit and economic national impact of the proposed project was so great that the Wurts brothers were able to convince enough investors and to raise the venture capital needed. This project became the first multi-million dollar privately funded commercial project in U.S. history. The project was organized as a corporation to be known as the Delaware and Hudson Canal Company. After formation the company under the Management of the Wurts brothers they began to design and build their mining and transport system.

The successful creation of this project constructed out in the Pennsylvania wilderness is a credit to the determination, perseverance and skill of 1830’s America. The system when completed became a huge success. The Carbondale fields became the principal supply venue for the very important Hudson River, New York and northern New Jersey’s developing industrial market. Over the course of the remainder of the 19th century the Delaware and Hudson Canal Company was responsible for shipping millions of tons of coal eastward. Along the way what the Wurts brothers started in the 1820’s created and grew into the U.S. coal industry which fueled America’s great Industrial Revolution.

As an industry unto itself the coal mining industry would create tens of thousands of mining related jobs, many of which were filled by immigrant labor. Among those who labored in the mines of Pennsylvania and West Virginia were many Irish, Germans Italians, Greeks and Eastern Europeans. These immigrant laborers would establish communities throughout the region each bringing elements of the cultural traditions into those mining regions. By so doing this industry created the patchwork of ethnic diversity still present in the regions today. On a personal note I can add that the coal mining industry plays a part both directly and indirectly in my own Italian American family heritage. My maternal grandfather Archangelo, born in 1881 first emigrated to the U.S. as a teenager in the mid 1890’s and found employment in the coal mines of Pennsylvania. His experience was in the deep mines the first of which built in the U.S. were in the Carbondale region. Luckily for me he didn’t like the working in the mines and eventually returned to his native province of Naples. There he met and married my grandmother and still later they both emigrated to the U.S. this time settling in Trenton in 1908.

Photograph of 19th century deep mine coal miners

The construction of the D&H rail and canal system was a project that required talented innovation. We should acknowledge that to the extent that innovation could enhance their enterprise it was highly appreciated and encouraged by the Wurts brothers as managers of the D&H Canal Company. As a result the Wurts brothers and their business the Delaware and Hudson Canal Company fostered several other noteworthy firsts in America’s industrial history. Their gravity based rail line across the mountains was the first commercially successful rail line in the U.S and the longest attempted or employed in the country. Obviously this line was unique in the development of rail transport in that it relied on gravity rather than being driven by a steam powered locomotive. Nevertheless it helped demonstrate the efficiency and advantages to rail transportation and several short distance rail lines, initially pulled by mule and then steam locomotion began to be developed.

Photograph of the D&H Canal rail line in operation

The Wurts brothers as managers were aware of the intensity of labor required to operate their “gravity line”. Looking to establish efficiencies they did experiment early on with steam driven locomotion purchasing a very early prototype steam engine from England for that propose. This engine, named the “Stourbridge Lion” was the first commercially employed steam locomotive in U.S history. Unfortunately this early steam engine was large, slow and underpowered for their needs. It lack sufficient force to pull heavy loads up steep inclines. They also found in their trials that the weight and vibrations caused by the engine’s use was undermining the supports for the wooden bridges they had built across ravines and streams and had caused the tracks to unhinge causing derailments. So the engine’s use was abandoned as impractical. Successful employment of steam locomotives would have to wait for several more advancements in track design and support design. Of note early U.S. steam powered rail lines were almost always built on relatively flat ground and stopped at major rivers as bridge construction failed to provide sufficient support for the weight of the engine and cars.

The success of the Delaware and Hudson Canal Company was noted and encouraged many other men interested in manufacture and related businesses. These individuals through their own entrepreneur efforts launched countless other industrial ventures and became the early founders of America’s Industrial success. Two examples of individuals directly affected by the D&H Canal venture are worth mentioning at this point. The businesses that these men would go on to create helped employ many immigrant workers including many San Felese.

WILLIAM HENRY

Mr. Henry I am sure is not a household name nevertheless I think his story is important to our San Felese Immigration tale. Mr. Henry started his business career by leasing and operating a Bituminous coal fired blast furnace in Belvidere N.J. in the early 1800’s. I should note historically that the existence of iron ore deposits in northwestern New Jersey had resulted in Iron ore mining and foundry/furnaces being constructed in that area since early Colonial times. The blast furnace that Mr. Henry operated had existed for over fifty years and had produced militia weapons for the colonists going back to the Colonial era.

French and Indian War. Although successful in New Jersey, Mr. Henry sought to capitalize on the use of cheaper Anthracite coal and the availability of newly located iron deposits in northeastern Pennsylvania. Mr. Henry would have to be regarded as a business visionary. He saw the relatively untapped resources of the Pennsylvania northeast as opportunity. He decided to relocate his business operation to Slocum Hollow Pa. an area where iron ore had been found and to construct a “blast” furnace there. In the early 1830’s there were no efficient Anthracite coal fed “blast” furnaces operating in the world. Mr. Henry together with his son-in- law and business partner Seldon Scranton raised funds and began to experiment with building a blast furnace that operated on Anthracite coal. After several failed attempts which resulted in several near bankruptcies he finally succeeded. In 1846 together with several of his son-in-law’s Scranton family relatives and other venture capitalists he formed the Lackawanna Furnace and Rolling Mills Company. Again, we have another example of innovation and perseverance coming together creating a new industry which carved success out of the American frontier.

Photograph of Pennsylvania miners in Open Pit Iron Mine

Employment at the Lackawanna Furnace and Rolling Mill Company steadily grew and the resulting population surge transformed Slocum Hollow into a bustling town renamed Scrantonia after the Scranton family. The named of the town was later shortened. By 1846 the mills were producing nails and other rolling stock for market. However, the big boost to the company came in 1848 when the Scrantons secured the contract to supply “T” rails for the Erie Railroad which was at this time building the Port Jervis to Binghamton rail line spur. Early railroad lines, in the U.S. were developed by constructing short extensions spurs. These lines developed over the course of decades rather than in large projects. Initially there were many Independent railroads that eventually merged or consolidated for efficiency and cost.

Probably because of its location and by shrewd and insightful management the Lackawanna Furnace and Mill Company eventually diversified. It became a unique operation in that it had corporate holdings in railroads, steel mills and coal production. As those who live in Buffalo know the Lackawanna Steel Company a successor company to the Lackawanna Furnace Company would relocate its track manufacturing Mills to Buffalo N.Y. in 1902. This occurred in order to bring the company geographically forward and closer to the iron ore supply chain which now was centered in the Midwest. Transportation, rail work, coal and steel production were all critical industries which supported the prosperity of the western New York region creating thousands of jobs.

JOHN A. ROEBLING

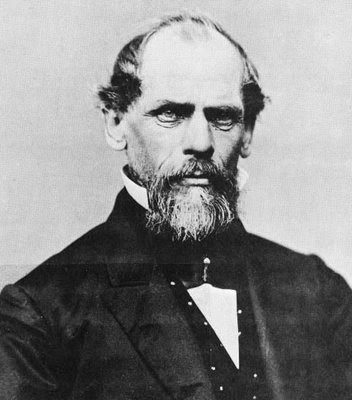

Another individual who would get his start and connects directly to the Delaware and Hudson Canal Company success is a young German immigrant by the name of John A. Roebling. Mr. Roebling immigrated to Pennsylvania from his native Germany in 1831. His original intention was to establish with fellow German immigrants a Pennsylvania farming community and help create a utopian agriculture cooperative. There was a romanticized movement in Germany at the time to which Mr. Roebling ascribed promoting such a agrarian living environment. It should be noted that Roebling was not a farmer by training or background but rather had studied engineering at university. After several years of less than successful farming labor Mr. Roebling started supplementing his income by doing surveying for the State of Pennsylvania. Roebling’s surveying work in and around the Carbondale area brought him to the attention of the Wurts brothers and the management of the Delaware and Hudson Canal Company. In 1838 they hired him initially to survey expansion routes for the Delaware and Hudson Canal Company’s Carbondale valley coal fields.

As part of his job duties Roebling would survey and engineer new expansion routes for the gravity powered rails. As old surface mine deposits of coal were exhausted, new deposit fields had to be opened. Each such expansion into new fields would require a limited redesign of the rail line throughout the valley to accommodate the extension.

When the D&H rail line was originally opened the coal cars were pulled by iron chains attached to pulley systems. Iron of the time was made into mostly wrought iron or cast. Iron chain links were of limited strength and were subject to individual link failure. Failure of individual chain links on steep slopes had the catastrophic result of runaway cars crashing down steep mountain sides. So common was the problem that for a while the rail line operated with blacksmith shops positioned along the routes to immediately address repairs as failures occurred.

It was eventually determined that the use of large hemp rope was safer and worked better and iron chains were replaced with large hemp ropes. At the time Roebling started his employment with the D&H canal Co. rope was the method used. Roebling noted that the large and expensive rope was subject to fraying and needed to be replaced frequently causing the line to shut down.. It was Roebling that suggested that he could produce a “wire” rope which he maintained would work better. Iron rope would offer enhanced strength without the weakness associated with links in chains. With the encouragement of the D&H Canal’s management Roebling began producing wire rope at a Mill he built in Pennsylvania. Testing of the product proved that it was a very satisfactory alternative to hemp providing vastly improved strength and far less fraying repair. The Roebling wire Mill factory got its start by supplying the D&H Canal company.

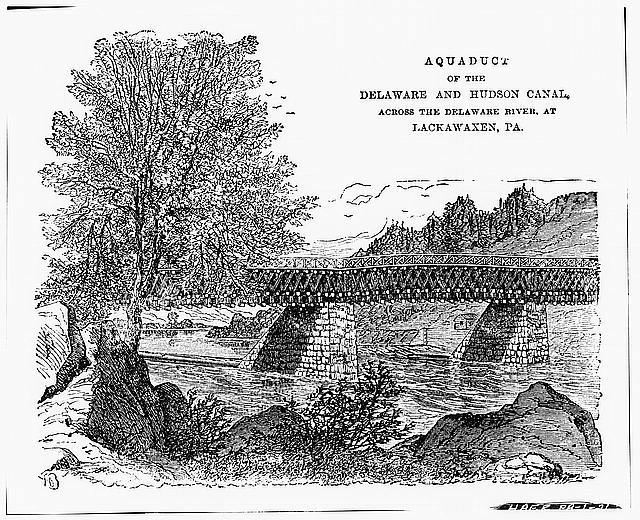

In addition, the D&H Canal Co. required an aqueduct be built across the Delaware River to supply water for its Canal system. Using conventional construction methods would have been very expensive. Roebling suggested to D&H management that a suspension bridge utilizing his wire rope as support could support a water trough. Such an innovative design could be built much less expensively and be more than adequate for the Company’s needs. Again with the encouragement of the D&H Canal Co. Roebling designed the first “suspension” aqueduct employing his wire rope to support the aqueduct. In building this aqueduct Roebling would develop many of the basic principles that would guide his future suspension bridge projects. In essence we see Roebling not only creating the wire rope industry but also some of the applications for the product.

Drawing of Roebling’s Aqueduct Suspension Bridge. Note Bridge is still in use now as a pedestrian crossing.

Photograph of John A. Roebling