Bridging the Delaware

By: Tom Frascella September 2014

John A. Roebling and the companies he founded have achieved an almost mythic stature in the annals of American Bridge building. The City of Trenton as the manufacturing center for the production of the materials used by his companies’ greatest successes is duly proud of its contribution. Trenton can rightfully boast that John A. Roebling and Sons the wire rope manufacturing company, and Roebling himself an innovative and brilliant engineer and bridge designer are forever associated with some of the greatest suspension bridges built in America. But Roebling was not the first U.S. engineer to design and build an American iron supported suspension bridge. In addition Roebling was not the engineer who built the first suspension bridge across the Delaware River. This feat of engineering was accomplished in 1804. Ironically that first suspension bridge across the Delaware River was built in Trenton, just a few hundred yards from where Roebling would later build his first Trenton wire rope factory in 1848.

Bridges are an important and critical part of the story of early American development, expansion and industrialization. In the early years of the United States the majority of its population clustered primarily along its coastal plains. As we discussed in previous articles shortly after the republic was formed enterprising individuals began to seek ways to access the great natural resources of the interior. At first, the rivers and sea lanes provided the only reliable routes for the transportation of goods and materials to and from the American interior. Over time use of the rivers and newly dug canal system was enhanced by technological advancements in nautical steam locomotion. However, to fully exploit the resources of the continent advances in connective networks of ground transportation had to be achieved.

Construction of an effective American East-West continental road network was blocked by mountain ranges, the Appalachian and Rockies, which hosted formidable peaks and gorges. In addition the country also presented hundreds of large and powerful rivers all of which primarily ran north-south. Obviously if east-west progress and continental coast to coast linkage was to be made a reality these obstacles had to be “bridged” and overcome.

During the colonial period and the first decade of the American Republic no substantial river in the whole of the country had been bridged. The bridges that were in service were primarily private structures over relatively minor streams and gullies for which tolls were privately collected for use. Most of the bridges were made of wood, “designed” and built by local carpenters with little knowledge of load capacities or stream torrent dynamics. These bridges were not “engineered” in the modern sense. As a result many of these bridges had very short lifespans, most bridges built during this era failed within twenty years of construction. Bridge “engineering” was in its infancy in early America. In fact trained “engineers” were in general in short supply and this shortage was one of the reasons that the U.S. military academy at West Point was established with a strong engineering curriculum. For the first century of our country’s existence many of the country’s engineers were West Point graduates. As manufacturing and industrialization began to slowly emerge in the U.S. it initially centered in the port and population centers of the Northeast coast of the U.S. As a result many of the first bridges spanning major waterways in America were built to span local rivers such as the Susquehanna, Delaware, and Hudson Rivers. Spanning these formidable bodies was no easy task but early American ingenuity and innovation were evident from the outset.

I am attracted to the story of early American bridge building not just because of its importance to the nation but also because early Lucanian immigrants arriving in the U.S. later in the mid-19th century were largely employed in land clearing, rail laying and bridge building. This labor intensive and back breaking work nevertheless provided needed opportunity to our ancestors. Although American bridge building was well under way by the time significant Lucanian labor arrived this type of construction played a vital role in our ancestors’ survival in America.

Two American “engineers” stand out in the early story and advancement of American bridge building, James Finley and Theodore Burr. It about these two individuals that the rest of the article is dedicated.

Judge James Finley

The first individual I would like to discuss is a fellow by the name of James Finley (1756-1828). As you can see from the dates Mr. Finley’s life intersects with the end of Colonial America, the Revolution and the establishment of the Republic. Mr. Finley is regarded as the first designer and builder of the “modern” suspension bridge. Sources vary on where Finley was born some citing Ireland and other sources colonial America. In either case we pick up his story when he settled in the Uniontown Pa. area where he initially took up farming after purchasing several hundred acres of land. Uniontown Pa. is located near Pittsburg which in the late 1700’s was still part of the country’s western frontier. In addition to farming Finley became a jurist as well as legislator in the 1780’s and 1790’s. In his role as a civic leader he was acutely aware that regional development required a better transportation system to the area. Frequently the rugged terrain made it difficult to get farm products to market or to import the machinery needed to grow business. It was evident that bridges spanning the gorges and rivers of the area had to be constructed but the expertise among local inhabitants didn’t exist. Up to the challenge Finley privately studied bridge building techniques. Because of the deep mountain gorges and the annual violent Spring river flooding Finley decided that “suspension” bridges were ideally suited for the terrain issues that confronted him.

The concept of building a bridge whose crossing deck was held in place by vertical ropes suspended from overhead lateral ropes has been around for millennium. Finley’s designs relied on replacing hemp ropes with cast iron chains linked together. This added substantially more strength and load bearing capacity.

During his career Finley built bridges across a number of early America’s most important East coast rivers, these included the Potomac River, The Schuylkill River, the Merrimac River in Massachusetts and the Lehigh River.

Finley, although a successful bridge designer never gave up his day job and his career as a Pennsylvania jurist is recorded from 1784-1789 and again as an associate Judge for Fayette County from 1791 until his death in 1828. In his lifetime, Judge Finley would find time to design and supervise the construction of between 20 and 40 bridges in Pennsylvania and elsewhere.

Although building that number of bridges is noteworthy in and of itself what is of special note is that his designs were all for “suspension” bridges. As I noted in my opening Judge Finley is considered the “designer” of the first “modern” suspension bridge. In fact Judge Finley is credited with building the first suspension bridge in the U.S. in Pennsylvania in 1796. Finley’s design as we noted relied on cast iron chain links the technology available to him. In 1801 Finley designed and built the seventy foot Jacobs Creek Bridge near Uniontown Pa. For this chain link suspension design he was granted the first suspension bridge design patent in the U.S. in 1808. Using chain links would become obsolete with the introduction and use of stronger iron cable for suspension of bridge decking begun in 1816. This introduction of cable suspension was an innovation which also was first introduced in Pennsylvania central districts. So by the time John A. Roebling immigrated to the U.S. in 1831 and took up farming and later engineering in central Pennsylvania suspension bridges were a known and accepted bridge type, especially in the central Pennsylvania area.

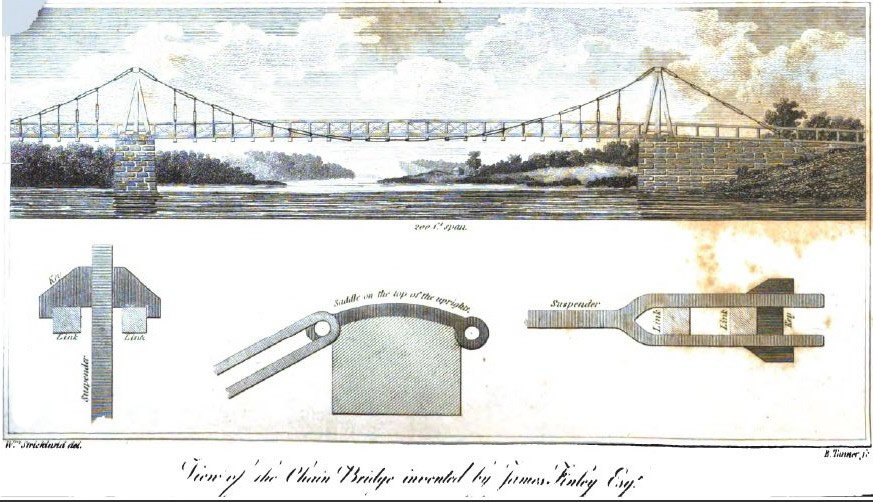

As the drawing below shows many of the features we consider typical for suspension bridges are apparent in the appearance of the 1801 Finley suspension bridge.

Etching of a Finley designed bridge probably the Chain Bridge over the Schuylkill

Theodore Burr (1771-1822)

The second individual I want to discuss in this article is Theodore Burr. Essentially Burr was also a self-taught engineer, carpenter and craftsman from Torringford, Connecticut. As Burr entered into the building field he too was aware that local wooden bridges frequently failed due to rot, flood, inadequate load distribution or some combination of all three factors. Burr was ambitious enough to begin a personal and disciplined study of European bridge design with a hope of understanding how to build better stronger bridges. By 1792 at the age of 21 Burr had arrived in Oxford, New York where he designed and constructed a grist mill and a dam to power the mill in 1794. Shortly thereafter he began to devote his attention based upon his studies to bridge building.

The type of bridge that Mr. Burr is most known for is his design and load enhancement of the wooden “covered“ bridge type. Generally, examples of this type of bridge still exist and are frequently depicted in early American etchings and rural American northeast photographs. The earliest attempts to strengthen this type of bridge and increase their longevity had the wooden supports for the bridge covered, hence the name “covered” bridge. In 1800 Burr built the first “stringer” bridge across the Chenango River in Oxford N.Y. His studies and early work on bridges lead him to develop a system of support and load distribution that would bear his name the “Burr arch truss”. Burr’s design is important because he arrived at his design based upon sound principles of load distribution and therefore his designs were “truly” engineered. In 1804 he was granted a patent for the Burr Arch truss design which became the most common method of design support employed in this type of very popular bridge building. As evidence of the quality of his building techniques and engineering one of his earliest major bridge construction projects was a four span bridge he designed across the Hudson River near Waterford, N.Y. in 1804. This bridge stood the test of time remaining in use until 1909 when it was destroyed by fire, not the elements. Because of his “engineering” skill Theodore Burr is known in engineering circles as the “father” of American bridge building. Between 1800 and 1818 Burr would be able to claim that he had successfully built forty-five bridges in various locations in New York, Pennsylvania, New Jersey and Maryland. In fact he was responsible for building nearly every bridge crossing on the Susquehanna River from Binghamton, New York to Baltimore Maryland. Today in recognition of his contributions a number of east coast covered bridge preservationist societies incorporate his name in their organization.

However having provided the above background information concerning Burr as the father of the truss bridge, it is interesting that only once in his career did he experiment and deviate from this design. In that one case he built a “suspension” bridge. In March 1798 the N.J. State Legislature authorized the raising of bonds for an interstate project in conjunction with State of Pennsylvania to build the first bridge across the Delaware River. The bridge was to be built just above the Falls at Trenton and would connect Trenton to Morrisville Pa. The Pennsylvania legislature passed a corresponding sister Act in April of the same year. Theodore Burr was selected as the designer of this bridge based upon his already growing reputation and his work on the Hudson River Bridge crossing.

The Trenton project presented some interesting conditions which in Burr’s bridge design had to be addressed before the project could start. From the Falls at Trenton northward the Delaware River is shallow maintaining an average depth of three to four feet. It is only south of the Falls that the River is considered a deep water body that ocean going vessels can navigate. One might think that the shallow water would make engineering this bridge “easy” however it actually presented unique problems. The river, especially north of the Falls was known to frequently freeze in winter. In the Spring the ice flow break-up and the flooding caused by melting snow from the mountains was known to cause severe flooding along the river bank and to send debris, logs and trees down river. Many thought that building a bridge at the Trenton-Morrisville location was destined to fail due to the above stated conditions. As a result it took almost six years to sell the bonds necessary for the project in the public market.

During the period between the Legislatures passing the Acts and the raising of funds Burr determined that the Trenton Bridge would be a “suspension” bridge. This decision has fascinated historians and engineers ever since. Burr not only had never designed a suspension bridge before but he never did again. The question is compounded by the fact that the decision was not made out of “engineering necessity. The Trenton Bridge was designed to have five spans with the shortest at 161 feet and the two longest at 203 feet. Span length was not the issue as examples of his other Burr arch truss bridges have spans as short as 60 feet but as long as 367 feet. So could have used his conventional design in the construction of this bridge.

Some historians have speculated that Burr altered his plan after being introduced to the designs of his contemporary Judge Finley who was designing “only” suspension bridges. Unfortunately Burr himself left little in the way of writing to address the question. Some historians have speculated that at this time in his career and life he became aware of the work of his contemporary Judge Finley with chain link suspension bridges and was simply experimenting with the design potential.

Whatever the reason that a suspension bridge design was chosen, Burr produced a design that was original and unique. The concept of a suspension bridge is ancient. What changed over the millennia was the materials used. In ancient times rope was used. In the 17th century forged cast iron chain was introduced for supports and later still iron cable. Finally steel wire rope became the material used in modern times. What is consistent in suspension design is that you basically see two lateral cables that are suspended between towers with vertical cables descending from the above cables to support the bridge deck. The cables above generally form a “U” shape between the two towers. Burr’s Trenton design instead suspend the chain link for the deck from a wooden laminated arches and then covered the arch with a roof. In essence the bridge is a sort of hybrid of his usual arch design, mixed with elements of suspension technology. As far as anyone can determine this is the first example of this design in world history.

Construction began on the Trenton Bridge in 1804. The piers and abutment supports were originally set at a height that exceeded the highest known flood height for the river at the time. However after completing the supports but before building the upper decking etc. the very next flood proved that the bridge piers were too low. Approximately two feet had to be added to the height of the supporting stone work. The bridge was completed and opened to the public with great fanfare on February 30, 1806.

On that date Theodore Burr and his workman led a great number of people across the bridge for the grand opening hailed by a seventeen gun cannon salute from both sides of the Delaware River. Seventeen cannons represented the seventeen States in the Union at that point. To get a sense of the pace of early U.S. infrastructure development although this bridge was the first built across the Delaware by the year 1841 a total of 12 bridges had been built across the river between Trenton and Phillipsburg. The Phillipsburg Bridge was the second bridge across the Delaware. I mention the year 1841 as a testament to the strength and durability of Burr’s design. There was a major flood on the Delaware in 1841 and of the twelve bridges only the Trenton and Phillipsburg bridges survived the flood intact. A brief history of the bridge is as follows. After the bridge was originally opened as a toll bridge in 1806 it was purchased in 1835 by the Camden-Amboy Railroad Company. The A&C railroad bought the bridge and laid rails for horse drawn train cars to be pulled across as the bridge was not strong enough to support the steam engines weight. This made the width of the bridge too narrow to handle the increasing concurrent pedestrian and carriage traffic. The roof of the bridge was removed and the bridge was widened in 1848.

So at the time that John A. Roebling moved his company to Trenton in 1848 this would have been the bridge just up river to his factory. As an engineer and suspension bridge designer himself he would have had the opportunity to daily look at this innovative and historic example of suspension bridge building. Among Roeblings’ greatest contributions to suspension bridge building is his own “engineering” advancements having to do with load displacement calculations in his designs.

To complete the story of the bridge, the wooden and chain link original bridge was replaced by a steel bridge in 1892. The rail line was by then owned by the Pennsylvania Railroad Company and in 1898 a parallel steel railroad bridge was built just north of the original piers. Both of these bridges were removed, but not their stone piers in 1903 when the Pennsylvania Railroad built a third bridge designed with concrete arches.

What is today locally known as the Lower Trenton Bridge was built in 1928 on the piers of Burr’s original bridge. In 1910 Trenton’s Chamber of Commerce, proud of its 19th century manufacturing history promoted the City’s industrial heritage with the phrase “The World Takes, Trenton Makes”, a slogan attributed to the late S. Roy Heath, the founder of Heath Lumber and a former State Senator. The slogan was altered and the message “Trenton Makes The World Takes was added to the south side of the Lower Trenton Bridge in 1935. At that point some began referring to the bridge as the Trenton Makes Bridge. The slogan still attaches to the bridge although the original sign has been replaced twice since 1935, once in 1981 and again in 2005. The present bridge and illuminated slogan have appeared in many photographs, movies and other venues over the past ninety years.

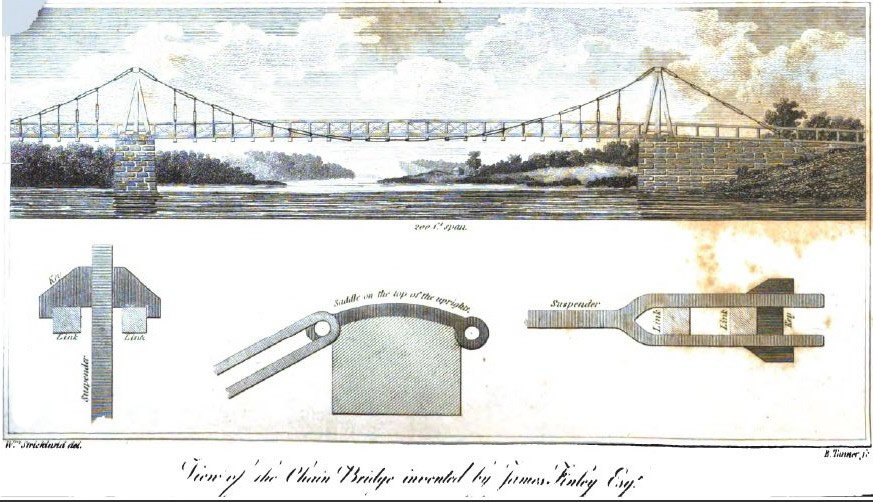

Photograph of Burr’s Trenton Bridge as it would have appeared from its Entry

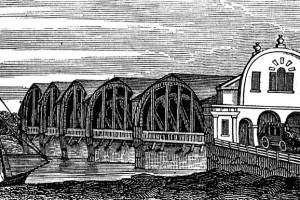

Photograph of Burr’s Bridge across the Delaware, side view

Photograph of the “Trenton Makes” Bridge

© San Felese Society of New Jersey